|

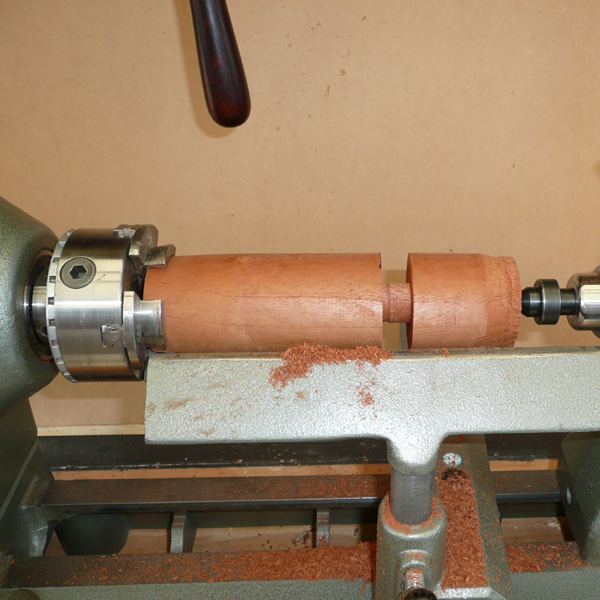

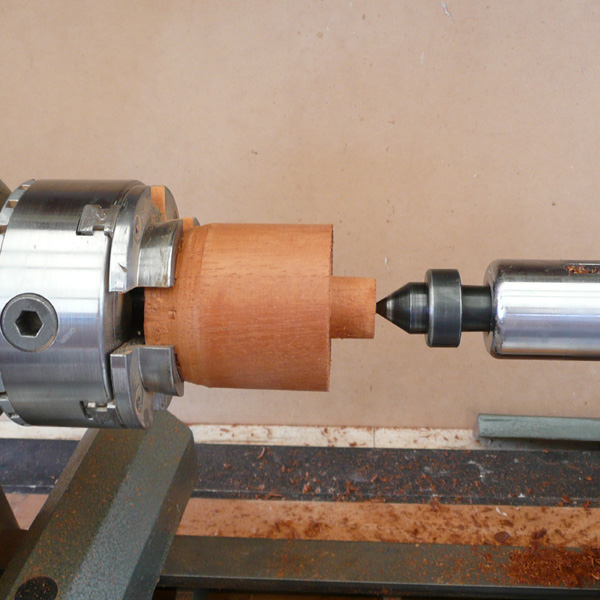

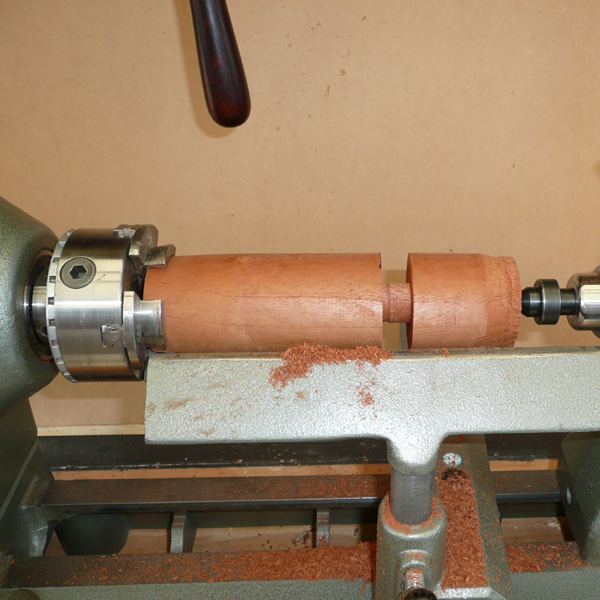

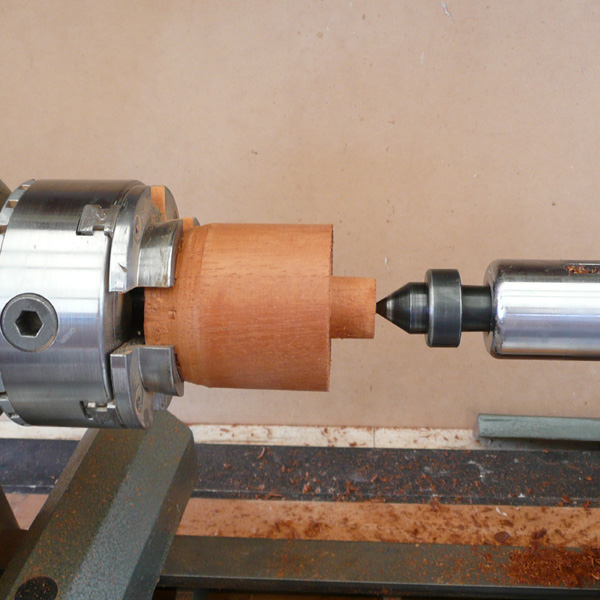

Step 1:

- Turn a suitable timber sample to 60mm diameter by approximately 230mm long

|

|

|

|

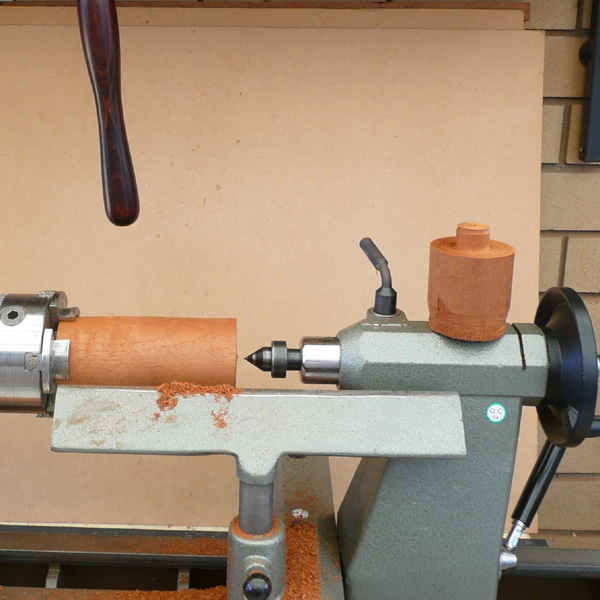

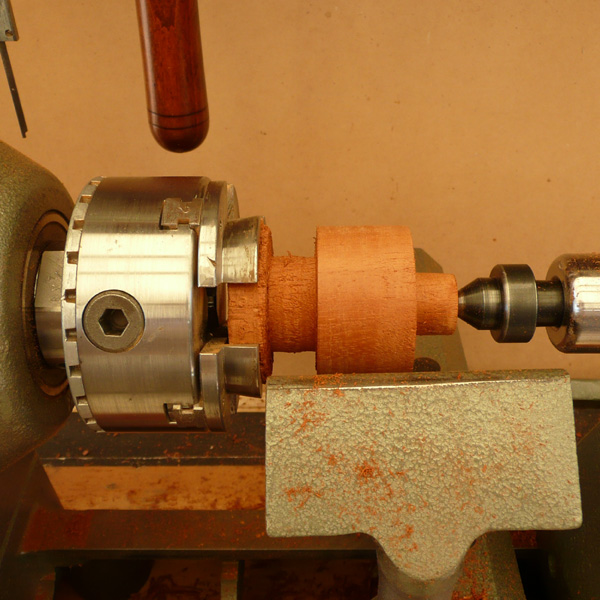

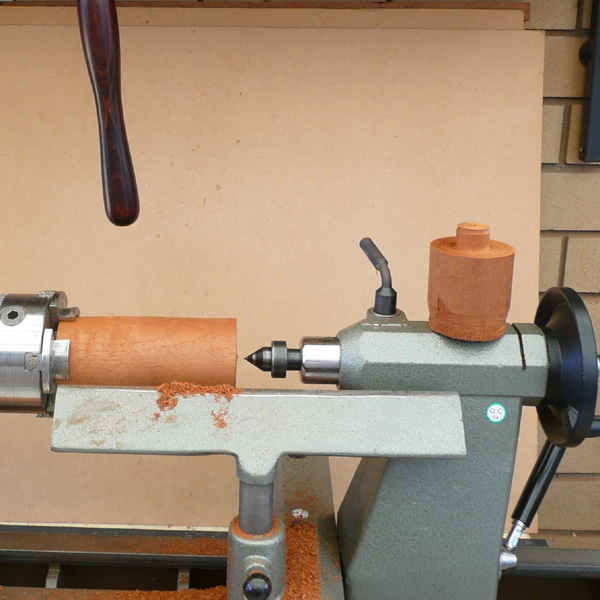

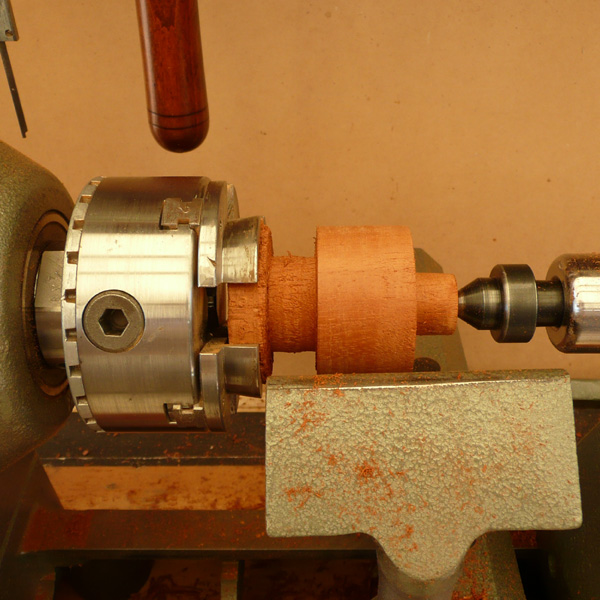

Step 2:

- Use a parting tool to separate the top from the body at 140mm.

- Leave 24mm diameter x 15mm long spigot on the end of the top...

|

|

|

- ...and make a centre mark by bringing your live centre up to the body before drilling.

|

|

|

|

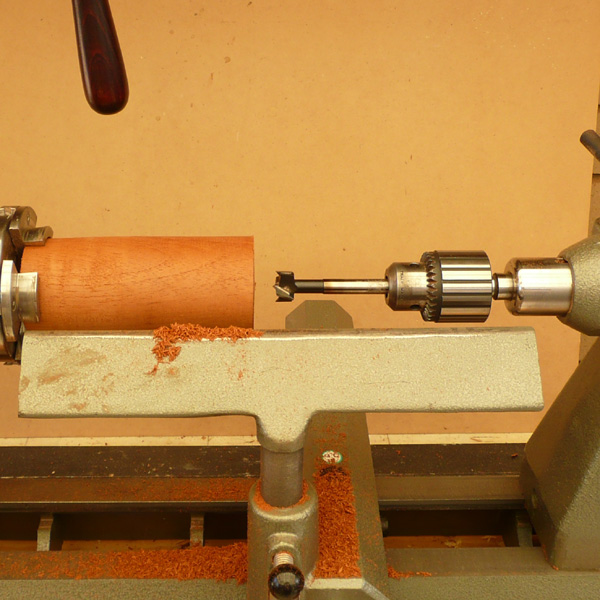

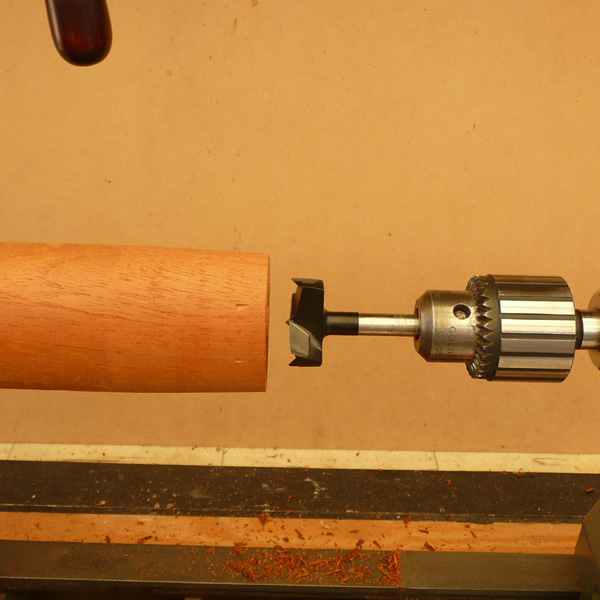

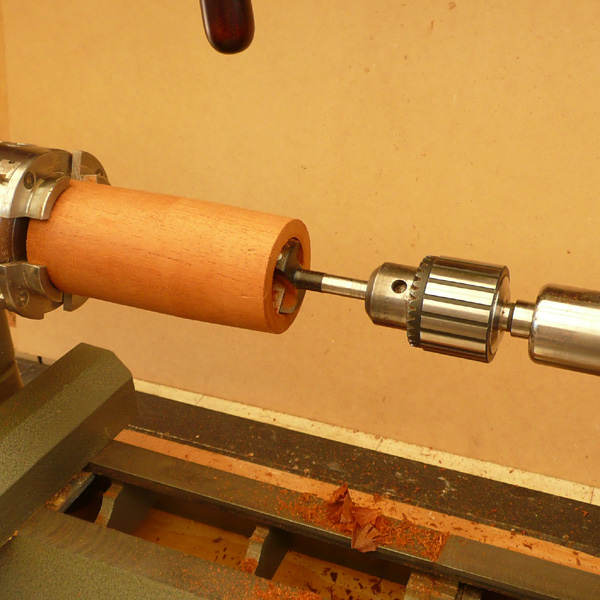

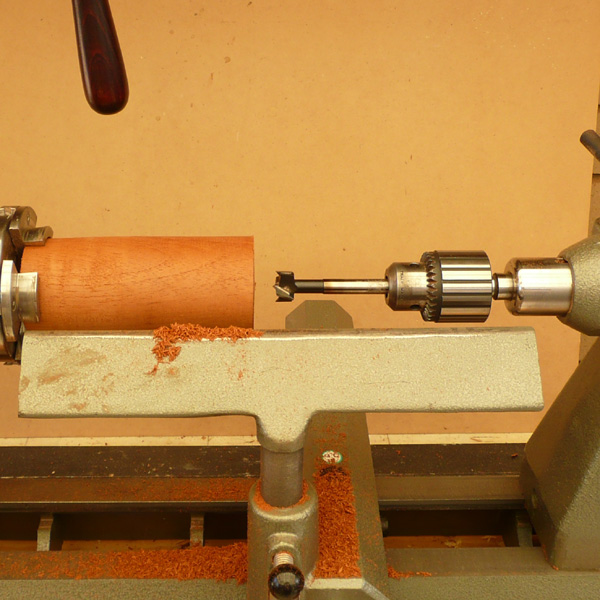

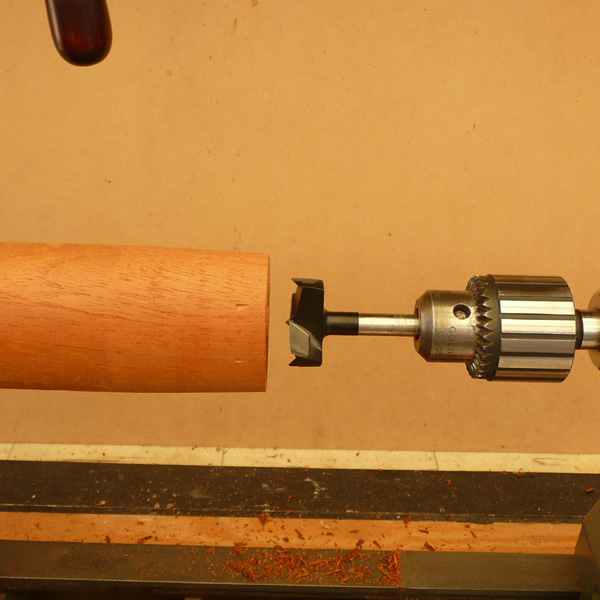

Step 3:

- Drill a 24mm hole half-way through the body while it is still mounted in the chuck.

|

|

|

| |

|

|

|

NOTE:

If using the ceramic pepper grinder kits (GRIND-7) you will need to drill a 28mm recess x 15mm deep at this stage of the process. This will allow the 'Ceramic' mill to into the base of the grinder.

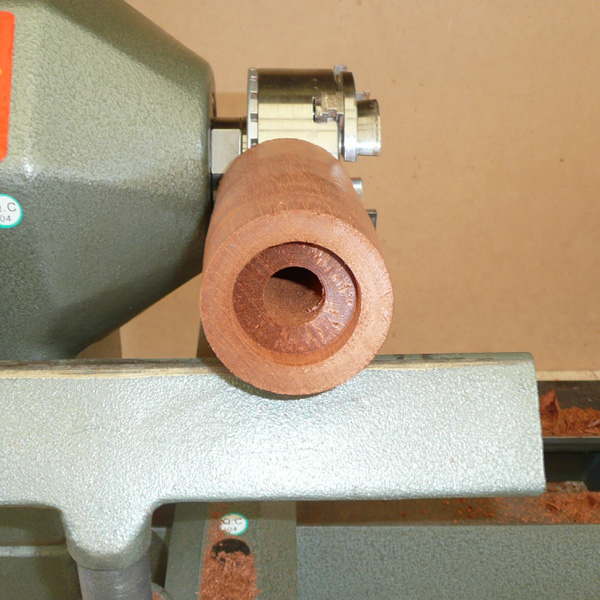

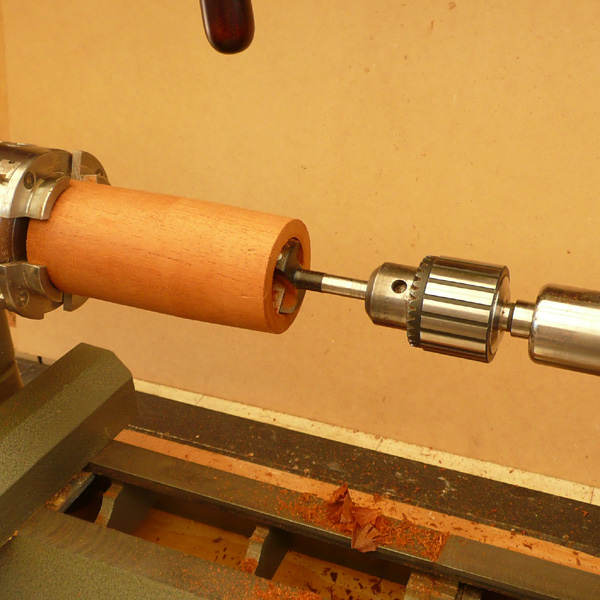

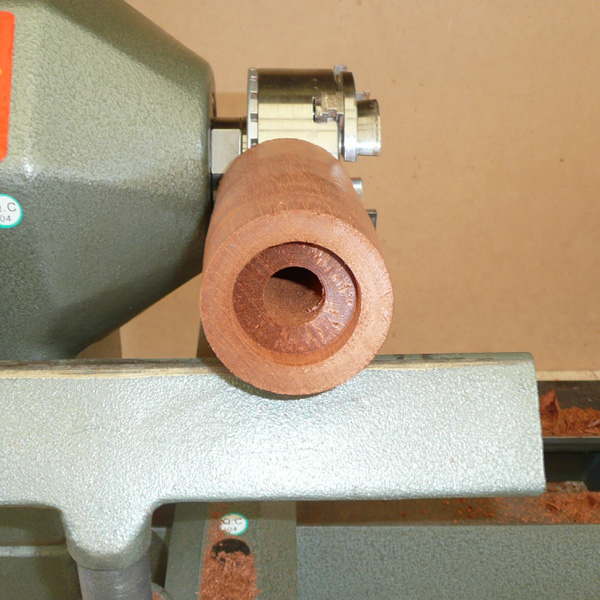

Step 4:

- Reverse the body in the chuck and prepare and drill a 40mm recess in the base of the body to a depth of 10mm...

|

|

|

| |

|

|

- ...then change back to the 24mm bit and complete drilling balance of centre of the body.

|

|

|

|

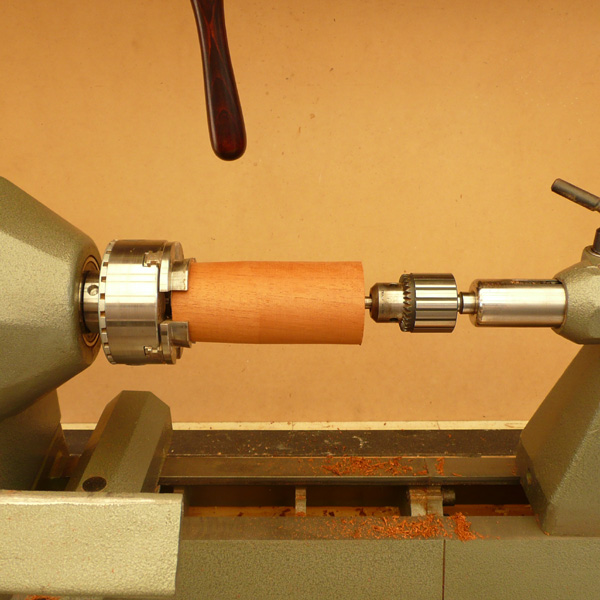

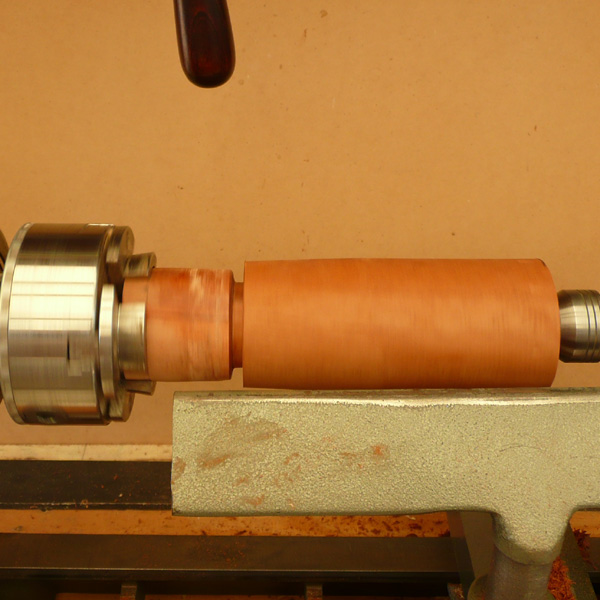

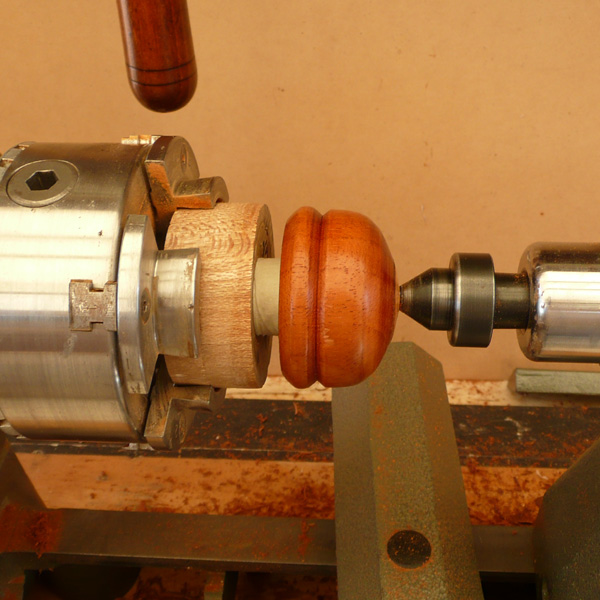

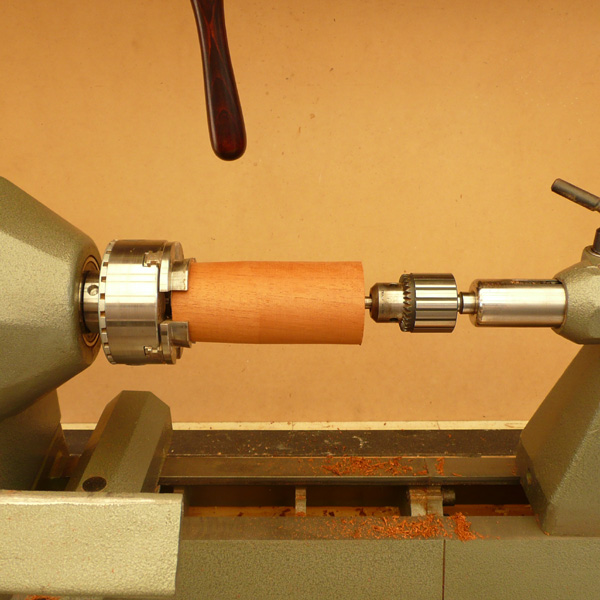

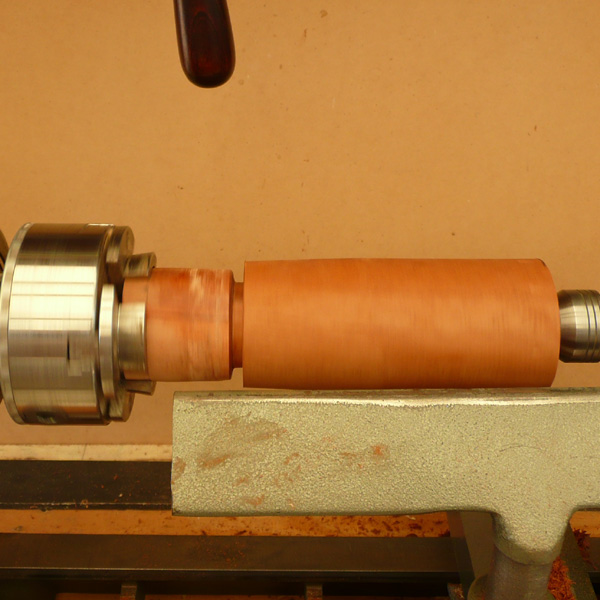

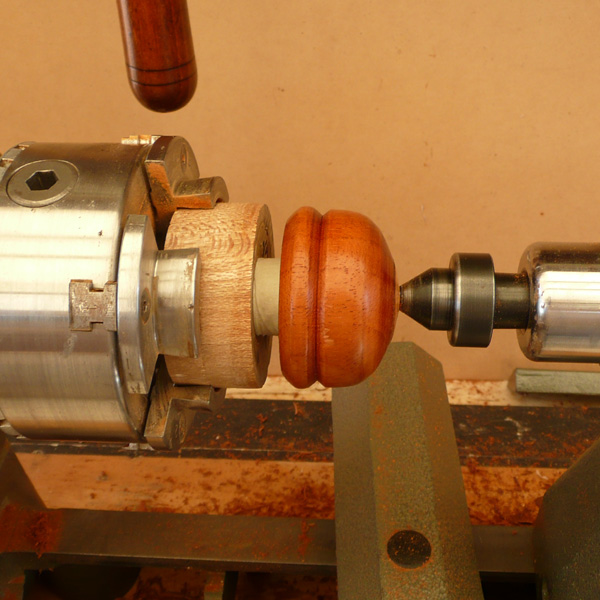

Step 5:

- Remount the body on the dummy 40mm spigot in a four jaw chuck.

- Bring up the live centre in the tail stock to align the body in preparation for final shaping and finishing...

|

|

|

- ..then turn the body down to 57mm diameter.

- This will also remove any jaw marks and indentations.

|

|

|

|

Step 6:

- Mark your preferred pattern on the body

- and turn and shape accordingly.

|

|

|

|

Step 7:

- Sand and finish with your preferred material.

- The project sample was sanded with 320 grit, 600 grit and 1200 grit papers.

- First coat was finished with U-Beaut EEE and final coat was finished with U-Beaut Shellawax Cream.

|

|

|

|

Step 8:

- Mount the top in the four jaw chuck with the 24mm spigot facing out.

- Align with the live centre, then check-fit the spigot into the 24mm hole through the centre of the body.

- Adjust the spigot accordingly until slightly loose fit achieved.

- Turn the top to 57mm diameter in preparation for final shaping and sizing.

- Drill 6mm hole through the centre of the top.

|

|

|

|

Step 9: Trial-fit grinder kit to body to ascertain final size required for the top. Allow for 8mm of thread to protrude from the top.

|

|

|

Also check that top and body match diameter where they join...

|

|

|

...then mark the top size as required, then turn waste end to approximately 40mm diameter in preparation for shaping top and finishing.

|

|

|

|

Step 10:

- Mark preferred pattern and then shape and finish.

- Part at nominated mark, check that all grinder kit parts fit as required.

- Then reverse mount the top into the dummy block in the chuck with pre-drilled 24mm recess, make any necessary adjustments to length or fit and then give a final finish to the top.

|

|

|

|

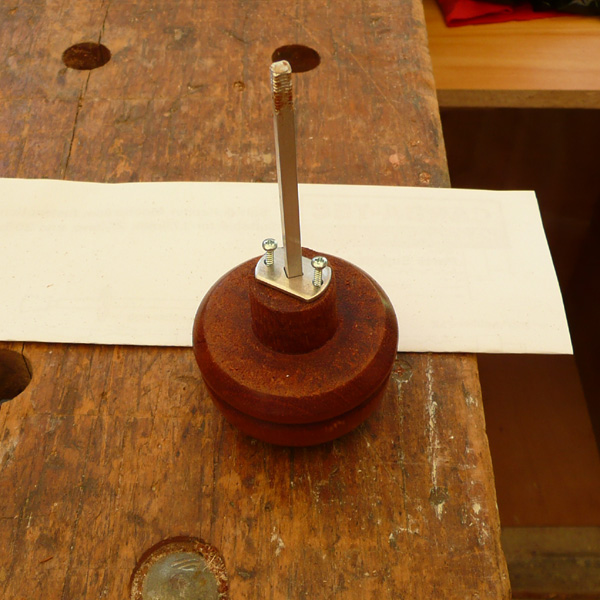

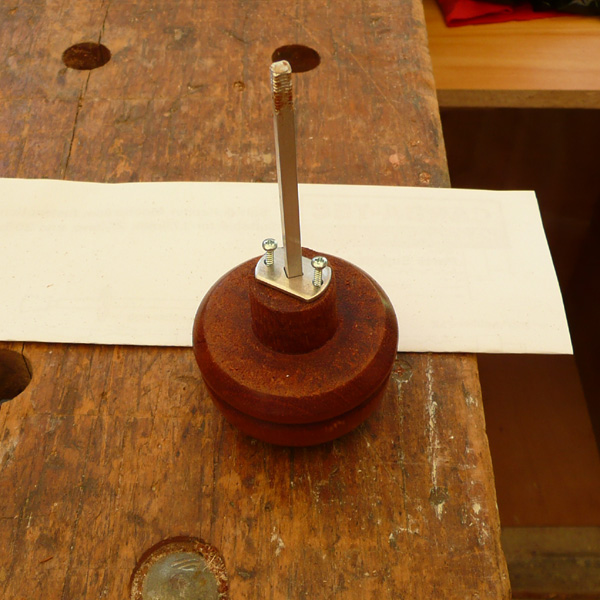

Step 11:

- Assemble the grinder.

- Fit small plate to 24mm spigot on the top.

- Use shaft provided to ensure plate is centred...

|

|

- ...then assemble grinder parts and fit to the 40mm recess at the bottom of the body.

- Pre-drill screw holes if using hardwood.

|

|

|

...and there you you have it, a beautifully made pepper grinder ready to use.

|

|