Celebrating 'Women in Wood"

Today, Friday,8th March is International Women's Day. This is the second week of our campaign celebrating "Women in Wood." This episode showcases seven remarkable female woodworkers and artists across Australia.

Be sure to follow our journey on carbatec.com.au and social media channels – Facebook and Instagram – as we share their stories and creations using the hashtag #womeninwood.

Jane James, Fine Artist

Queensland

https://www.janejames.com.au

https://www.instagram.com/janejamesfineartist/

Can you tell us a little about yourself and your craft?

My father was, and continues to be, my primary woodwork teacher and inspiration. He let me use his woodworking machines and tools as a child (which horrifies me now!) and was very generous in his knowledge. He passed his tools down to me a couple of years ago, saying that at ninety, he was finally going to stop using the big machines... and then promptly replaced them all! My degree was in Fine Art and Design, and I then entered a postgraduate programme in furniture design and fine woodwork. I have worked as an artist for the last thirty years, and have only gone back to furniture in a big way in the last two since I’ve had Dad's tools.

Where or who do you draw your inspiration from?

My inspiration comes from many sources, but I am driven in both my artwork and woodwork by a love of design. For me, any object I design and make, no matter the use, must be aesthetically pleasing, functional, and very soundly jointed. This means (generally) over-engineered, which seems to be something I’m notorious for!

What has been the most challenging project for you this far in your journey?

One of the most challenging projects recently was a bespoke Blackwood coffee table that contained display drawers with concealed mechanisms for a lifetime’s collection of perfume bottles. The whole table was designed for this function, but also to fit with existing furniture in the residence, and was done from rough-sawn material sourced from a mill, all the way to the final finish.

What would you say your proudest achievement to date is?

My proudest achievement is probably that I'm entrusted to design and produce a piece for people - it humbles me whenever I’m asked.

What advice would you provide to someone considering woodworking as a creative pursuit?

Spend time playing! I learn far more when I don’t have the pressure of producing a perfect object. And the same is true of painting, it frees you to explore techniques and ideas without the burden of feeling everything must have a product at its conclusion.

Isabel Atienza, En Mina Leather

Queensland

https://www.enmina.com.au/

Can you tell us a little about yourself and your craft?

I'm Isabel Atienza, the founder of En Mina Leather. I specialise in creating exceptional leather storage solutions for tools, handcrafted right here in Australia from Australian sourced materials. As a self-taught sewer and leather crafter, I started this journey in 2017 out of frustration when I couldn't find the perfect leather bag I needed. Since then, I've honed my skills and expanded our offerings to provide the woodworking community with high-quality, Australian-made leather goods to store their beloved tools.

Where or who do you draw your inspiration from?

Firstly, I'm inspired by the tools themselves, what they do, how they are used and the craftsmanship that goes into creating them. I also find inspiration from the woodworking community, seeing their dedication and passion for their craft. Witnessing the process of crafting a leather product with my own bare hands and tools, with the intent to safeguard the tools of fellow artisans, who will then use them to produce something of their own, brings me immense satisfaction. Additionally, Australian tanneries and the incredible variety of leather products that we have in this country inspire me with their commitment to quality and sustainability.

What has been the most challenging project for you this far in your journey?

One of the most difficult challenges has been recreating pre-loved leather handbags. This task demanded meticulous planning, precise measurements, and a unique approach to reverse engineering. Understanding the intricate construction, materials, and techniques used before beginning the projects was crucial. These challenges truly tested my abilities to the limit, not to mention the constant fear of not meeting expectations! Nevertheless, the final outcomes proved immensely gratifying.

What would you say your proudest achievement to date is?

Having my woodworking products available Australia-wide on the shelves of a high-end woodworking tool retailer in Australia. Thank you, Carbatec! It's a testament to the quality and craftsmanship of my leather products, and it has given me the confidence to continue pursuing my passion and providing the woodworking community with products they love.

What advice would you provide to someone considering woodworking as a creative pursuit?

Start small and practice regularly. Don't be afraid to make mistakes, as they are opportunities to learn and improve. Seek out resources such as books, tutorials, and classes to expand your knowledge and skills. Lastly, surround yourself with a supportive community of fellow craftspeople who can provide guidance, inspiration, and encouragement along the way.

Maddie Bidgood,

Carbatec National Retail Manager

Queensland

Can you tell us a little about yourself and your craft?

Creativity runs through my family's veins. I was destined to create and be involved in the industry in one way or another! I come from a long line of craftsmen on my father’s side and an even longer line of businessmen on my mother's. So I suppose you could say that my current position here as National Retail Manager at Carbatec is a perfect representation of my bloodline and is probably exactly where I am currently meant to be.

I grew up with my father, who started his working career as a Bricklayer and Carpenter and later created a successful building company, which he is only stepping back from now at the ripe age of 66. I was a fairly curious child, growing up visiting building sites on Saturday mornings, watching the improvements carried out on the homes we lived in and being shown many of my father's creations across Brisbane whilst out driving.

When I left high school, I wasn’t really sure what I wanted to do, and I ended up working in management at my local fast food chain, that was my part-time job through high school. My calling was not this. I felt I needed a skill, something I could travel with, something that was useful... and the penny dropped, I wanted to do a trade! I wasn't particularly interested in Bricklaying or Carpentry like my father, mainly due to the exposure to the elements, so I looked into Cabinet Making. I soon obtained an apprenticeship through a company that had a 'female in trades' program that supported me all the way through. My first placement, strangely enough, ended up being with a company that was well known to my father, as they had completed work for each other nearly 20 years before.

The physical demands of the work were hard to get used to, and the attendance of Tafe throughout the four years for theory components was a little uncomfortable at first, being a 23-year-old woman in a class full of 18-year-old males. However that soon disintegrated as I became more confident in my skill and ability.

Learning my trade predominantly in kitchens and bathrooms or residential joinery was only fulfilling to a certain extent. What I found most enjoyable was when the project scope incorporated the use of solid timber. The feeling of working with wood was unmatched. I started to take offcuts home and create nickknacks I could gift and then branched into more functional pieces. Today, I play with the practical principles I learnt in my trade and the creative aspect of myself. I would like to explore further through the addition of textures and other materials being incorporated into my works.

When I completed my trade in 2020, the company I was working for had to reduce costs. Fortunately, I secured a job at Carbatec as a Retail Salesperson. I saw the uncertain time as the perfect opportunity to get off the tools and do something different while staying in a similar industry! Even though I live and breathe the industry, I don’t allow anywhere near as much time for further learning and development of my craft as I would like - I’ll be changing that! Watch this space!

Where or who do you draw your inspiration from?

If I were to speak about a constant inspiration in the form of a person, it would be my father. His intelligence and practicality have really given me something to aspire to as I’ve grown up. And as far as creativity is concerned, we share a love for all things that look and feel earthy!

My father also taught me about many different species of fish at a very young age, and I recall asking him when we were out driving, and I would see a body of water: ‘What type of fish do you think are in there?’ As an adult, I relate this question to the one I ask myself now: ‘I wonder what the wood on the inside of that tree would look like?’ Or ‘I wonder what that wood would be like to work with!?’ I find the individuality of each piece of wood inspiring. I often end up hoarding pieces that have provided me with a project idea to undertake upon sighting the piece of wood, not having a project in mind prior…. (It’s kind of backwards, I know haha!)

I can’t leave out the obvious, though… The world around me inspires me every day! I get to live and breathe woodworking, and I hold a great appreciation for that.

What has been the most challenging project for you this far in your journey?

It would have to be my personal house renovation. My partner and I carried out a complete transformation of our house over the period of a year during the weekends, whilst working full time. It not only took prior knowledge from both of our backgrounds, plus my father’s support and skill, but a mountain of energy, determination and resilience to produce the most wonderful space that we now call home.

What would you say your proudest achievement to date is?

Writing this allowed me to fully reflect on my journey so far, which has made me feel a real sense of appreciation for experiences, people and where I am today. The appointment to my current role here at Carbatec goes down as a very proud achievement. I was able to use my transferable skills to obtain a job I would have once only wished for.

What advice would you provide to someone considering woodworking as a creative pursuit?

Ask questions, get curious and never be fearful of making mistakes. Sometimes, they’re the best teachers.

Rose Squire, Carpenter and Instructor

South Australia

https://www.onthetoolswithrosesquire.com/

Can you tell us a little about yourself and your craft?

I am a qualified carpenter builder, self-employed, in the industry for over 40 years. I am engaged one day a week at Burnside Shed as an instructor supervisor for Women's shed day and also have been instrumental in getting a women's shed up and running at Laratinga Mount Barker shed.

I have a business called On The Tools With Rose Squire. I offer one-on-one carpentry DIY instruction and also classes on demand.

What would you say your proudest achievement to date is?

My greatest achievement was starting to build my own house at age 18 it took me five years part-time, and I did pretty much all of the work myself apart from the electrical and plumbing work. The good news is the house is still standing, so I must have done something right!

What advice would you provide to someone considering woodworking as a creative pursuit?

Don't be afraid to give things a go, expect to get it wrong sometimes and expect that it will take twice as long to do as you think it's going to.

Fix It Sisters, Women's Shed

New South Wales

https://www.instagram.com/fixitsistersshed/?hl=en

Can you tell us a little about yourself and your craft?

The Fix it Sisters Shed is a not-for-profit organisation that empowers women of all ages in southern Sydney with practical and creative skills through educational workshops and facilitated DIY sessions. We also coordinate and volunteer for various projects throughout the community.Our current projects include traineeships for domestic violence victims, a mentoring program with students and building penguin burrows for the NSW National Parks and Wildlife Service. If there is a need for the Fix it Sisters and we can practically help, we are there! In addition to our community projects, we’ve also run a number of fun and educational workshops in local schools across southern Sydney.

Fix it Sisters was the brainchild of co-founders, Linda Prince and Lynn Kristensen, who met on a woodwork course in 2015. They struck up a friendship, discovered their mutual passion for helping women to learn new skills and an idea was soon born! After lots of hustling and get-togethers around the workbench, Fix it Sisters was officially launched in September 2018 with an all-female volunteer Board of Directors. Our aim is to build a social connection with a diverse range of women and girls (over 12 years) in the community, but with a particular focus on supporting new migrants, refugees, widows and domestic violence victims to become independent, skilled and confident. We're all about changing social norms and enabling women to reach their potential and find new passions in a creative, safe and supportive environment.

Where or who do you draw your inspiration from?

When the Fix it Sisters Shed were asked if we would build 20 burrows for the Little Penguins on Lion Island, we couldn’t say yes quickly enough. How could you not help these wonderful Little Penguins? It was an exciting brief - 20 concrete and perlite burrows to be ready for the start of the breeding season. They were a brand new design, and the Fix it Sisters’ job was manufacturing them. We had sore hands and bad backs when we were making them over a few months, but the pain faded away when we travelled with our precious cargo by barge to Lion Island to help install the burrows - a joint effort between National Parks and Wildlife, the land care volunteers and us.

Now, we have been asked to make ten more burrows for the Little Penguin colony off the NSW South Coast. We seem to be making more and more habitats for native animals, Bird Boxes, bee hives, and micro bat boxes.

What has been the most challenging project for you this far in your journey?

Building 2 floating islands for Sir Joseph Banks Park for the black swans.

What would you say your proudest achievement to date is?

The floating island was a great success, and we had five beautiful signets.

What advice would you provide to someone considering woodworking as a creative pursuit?

Go for it and give it a go! Come and join the Fix it Sisters Shed at Kyeemagh!

Kathryn Honor, Woodcarver

New South Wales

Can you tell us a little about yourself and your craft?

I have always used my hands not only to create but also to relax. Woodcarving came about as I was after a bit of a change from my usual crafting of botanical drawings, watercolours, embroidery, and knitting. I started woodcarving in June 2017 by just turning up at Sydney Woodcarvers, Epping Branch. The group teaches new members to complete a relief carving. This prompted me on my woodcarving journey with people who had a similar interest. I then attended Sturt Summer and Winter Schools and short courses to extend my skills with other carvers, including Jeff Donne, Hape Kiddle, and Carrol Russell.

I know there are a lot of people who like just to watch YouTube videos but this is not my preferred way of learning! I think this comes from being hands-on as I have a technical background as a Quantity Surveyor and currently work full-time in Higher Education.

Where or who do you draw your inspiration from?

At this stage of my journey I have not just settled on any one area of woodcarving. I still have a piece of relief carving going, as well as spoons, greenwood, animals, comfort birds, hearts, and any other items I feel the necessity to carve.

There are so many excellent carvers overseas and in Australia, I love the traditional work of Grinling Gibbons, the Pinwill Sisters. I am also drawn to the more modern styles of Emil Milan and current contemporary carvers like Hape Kiddle, Grant Vaughan, Carol Russell, and all the people I have met and carved with through Sydney Woodcarvers and courses.

Whilst skills and techniques come from teachers, magazines, and books, my inspiration primarily comes from the world around me. I love nature and try to bring this into each piece I create. I am also very drawn to symmetry. This year, I am contemplating a series on leaves.

What has been the most challenging project for you this far in your journey?

Probably my first piece. It was supposed to be an orchid in relief, but it turned into a fantasy flower and ended up a weird butterfly! I still have it, but it is not something I would show to others. It does, however, show the vital lesson that you have to keep going, learn the techniques, build the skills, and then the carved pieces will come to life. I believe in lifelong learning, and that my journey will be different to others as we all take different paths!

What would you say your proudest achievement to date is?

It's when I complete a carving, display it, and people want to reach out and touch it. I love a beautiful tactile finish that feels soft and flawless. If you're going to reach out and touch one of my carvings, I have achieved this goal!

What advice would you provide to someone considering woodworking as a creative pursuit?

Practice the technique and skills. Knives and gouges should be sharp; handle them with respect. Read, study, attend classes, and become a lifelong learner!

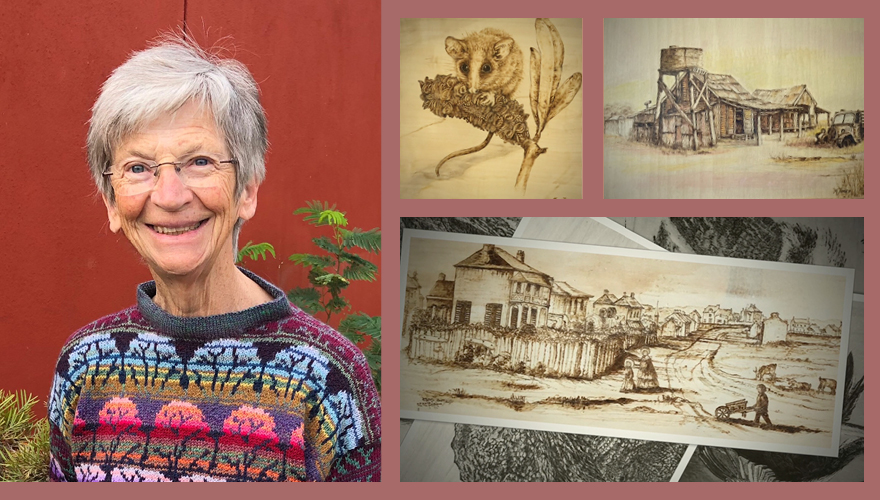

Maria Jones, Pyrography Artist

South Australia

https://www.anart4life.com/community-art-the-growth-of-the-victor-harbor-creative-community-part-four/

Can you tell us a little about yourself and your craft?

Since I first drew curves and lines with a pyrography pen five years ago, I have completed over 50 works, covering a wide range of subjects.

I’m now a member of the Victor Harbor Regional Gallery and over the last two years, have sold over 25 works.

Where or who do you draw your inspiration from?

My inspiration comes from local scenes, portraits, people and their activities, flora and fauna

What has been the most challenging project for you this far in your journey?

I continue to be challenged by capturing accurate detail and the addition of colour to my work.

What advice would you provide to someone considering woodworking as a creative pursuit?

As with all woodworking projects the selection and preparation of the timber is all important. Always purchase the best tools you can afford, and always use them safely. Working in a clean environment is essential, wear a mask and use a small fan to extract smoke. Wood smoke can be very acrid and should not be inhaled. Always store hot pens on a secure stand, and always turn the pyrography equipment off before you move from your workstation. Then... practise, practise, practise and enjoy your achievements!

Emily Taylor

Western Australia

Can you tell us a little about yourself and your craft?

I have always loved timber but only started ‘proper’ woodwork in the last five years. After buying my first home, it became apparent that my taste in furniture was way out of my budget. Joining the Women Working With Wood opened up a world of possibilities for me. I embarked on my first big project, a floating timber vanity for my bathroom. Around the same time, I did a spoon carving workshop with Greg Miller from The Joy of Wood. I whittled many spoons in my spare time; in fact, this kept me sane during COVID. While my woodworking arsenal now incorporates an array of modern technology, I always hand-finish each project because I think it gives it character and soul.

Where or who do you draw your inspiration from?

I love mid-century modern organic curves and minimalist designs. I follow Foureyes Furniture and Pedulla Studios. I am blown away by the skill and workmanship that goes into their projects. YouTube is a great rabbit hole for discovering new techniques and ideas to fuel my creativity.

What has been the most challenging project for you this far in your journey?

I design all my projects using Fusion 360 CAD software, relying on video tutorials and lots of practice to develop my skills. Last year, I embarked on a new frontier by venturing into CNC machining at the Lake Monger Community Shed. This endeavour demanded a further refinement of my abilities as I delved into programming machining cut paths. One of my notable achievements was crafting a delicate jewellery stand from reclaimed floorboards. The process was riddled with challenges and setbacks, each presenting invaluable learning opportunities. Through perseverance and numerous iterations, I fine-tuned every detail, ultimately achieving a workpiece that fills me with a deep sense of satisfaction.

What would you say your proudest achievement to date is?

Last year, I crafted a shoe stool for my bedroom using Western Australian Blackbutt. To my delight, this creation clinched the first prize for furniture in The Fine Woodworking Association’s Out of the Woods competition. My favourite part of this project is the refined curves. I learned some basic tool sharpening techniques, allowing me to hand shape every curve using a Veritas miniature plane and a spokeshave. Countless hours were devoted to sanding, ensuring seamless joinery, followed by many applications of finishes. The final challenge was upholstering the cushion, which served as both a hurdle and a valuable learning experience, adding the perfect finishing touch.

What advice would you provide to someone considering woodworking as a creative pursuit?

Find a community shed you can join and sign up for local workshops. Woodworking is a craft that demands both time and patience. Rushing or cutting corners often leads to mistakes. Take your time, embrace the process, and enjoy the journey of honing your skills.

Katie Richer, Adsum Richer Things

South Australia

https://www.instagram.com/adsumricherthings/?hl=en

Can you tell us a little about yourself and your craft?

Woodworking is basically something I grew up with. My dad used to run an office furniture business in the late 1980s/early 1990s, and some of my earliest memories are of me running around the workshop, helping with simple tasks, that kind of thing. I got into woodworking myself about 8 years ago when I was on maternity leave and wanted to make some cutting boards as Christmas presents for friends. I continued partly as a way of spending time with my dad, partly to learn and preserve the older techniques, and partly because I like learning new skills.

I started Adsum Richer Things almost by accident. Dad and I went to a cafe and got talking to the owner, who was in the cafe at the time. By the end of the conversation, he had commissioned us to do a bunch of table tops, menu boards, serving trays… that was in 2017, and Dad and I have been doing jobs here and there ever since. In addition to those kinds of jobs, I also made items to sell at markets (although I haven’t done many since the Covid pandemic).

These days, I’m back teaching at a high school, and I’ve mostly settled into woodturning. What I do on the lathe varies according to my mood, but it’s usually some kind of homewares: bowls, rolling pins, cheese knives, pens, and so on. I take on commission work when my teaching schedule allows, and my next goal is to get some qualifications to teach Design Technology (specifically woodworking/woodturning) so I can get my students hooked - err, interested - in this amazing field.

Where or who do you draw your inspiration from?

A lot from my dad. He’s long retired now, but has been in some form of woodworking for the past 60-70 years. I got into woodworking because there is this wealth of knowledge he possesses, lots about old techniques, and how to use old/obsolete tools. I’m trying to learn as I can, so the knowledge survives in some form. It always comes down to learning a new skill or technique then perfecting that technique. You could say my inspiration is the joy of learning a new skill.

What has been the most challenging project for you this far in your journey?

Two things come to mind. The first is when I decided that my house needed a built-in bookcase with cupboard storage underneath. It’s floor-to-ceiling (and I have 9ft ceilings) and 4.5m long along one wall. My dad and I got the material and hauled it all into our cramped workshop, and machined it all up there. We’re talking System-32 drilling, edge banding, cabinetry, there’s a solid wood bench top between the cupboards and shelves…there was a lot going on! We then took all the pieces to my house and assembled them in place. Lots of on-the-fly adjusting/fitting/trimming to make it ‘look right’ and fit properly in the space. I learned a lot about what cabinet makers and installers do in their day-to-day work.

What would you say your proudest achievement to date is?

Probably the fit-out at the Cotto Cafe in Prospect. As far as I am aware, they are still using our things, the custom blackwood tabletops and bench tops we made are still holding up well (better than the tops they got from elsewhere!), and the espresso machine still has our customisation.

What advice would you provide to someone considering woodworking as a creative pursuit?

Honestly, figure out a way to just give it a go! You don’t have to start by going all out with top-level equipment: my first midi lathe was bought for $100 from the old Trading Post paper! My first lathe tools were a surplus set from a local school. You can do a lot with basic tools, and as you spend time in the craft, you’ll find out what tools you need to purchase or replace with higher quality.

If you want to try something but can’t spring for the equipment - look up short courses. TAFE, WEA, and various hobby associations all do them. Say you want to try woodturning but can’t afford a lathe - call up your local woodturning club. In Adelaide, the three main ones are Northern Turners, Southern Turners, and Western Woodies. You’ll find that the majority of members are men, but they are generally very welcoming of new members who want to learn.

It follows that you will want to find a mentor or teacher, someone experienced in the craft, to learn from in a safe way. You might end up with more than one!

You might find something cool on YouTube that you want to try, but your mentor will help you to do that in a safe way, or help you modify the project so that it is safe and achievable for you at your skill level. |